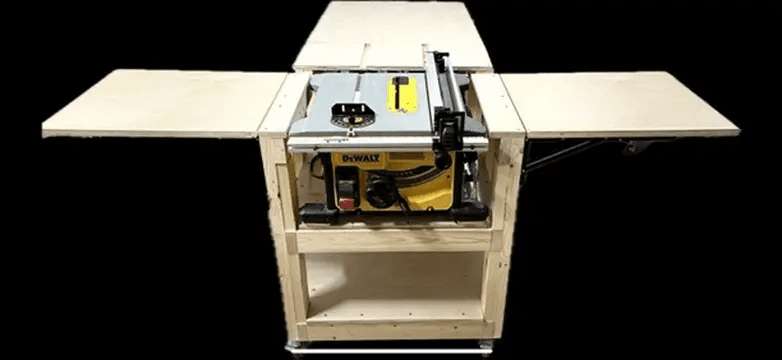

Expandable Outfeed Table

A rolling outfeed table for my table saw with folding wings and storage underneath. More complicated than expected, but I made it happen in the end.

3 weekends

October 2025

Materials

Techniques

Tools Used

Gallery

Build Notes

I happened to see this project on Bear Mountain Builds, and it caught my attention because I had the exact same table saw – one I'd scored for half price in brand new condition off Facebook Marketplace. The only problem? I didn't have a proper surface for it.

Why not build an expandable outfeed table that rolls, has storage underneath, and fits perfectly in my garage?

Confidence from the Workbenches

After completing the modular workbenches, I was feeling confident. I knew this project would have a similar frame construction using half lap joints – attaching 2x4s together and leaving equal space on the sides to create the joint.

How hard could it be?

More Complicated Than I Thought

Turns out, harder than expected. I learned a lot of lessons and made a lot of mistakes on this one.

The biggest struggle? Pocket holes. I have so much trouble gauging the right depth for pocket screws. In some instances, I just gave up and drilled the plywood directly into the frame because I got sick of trying to make the pocket holes work properly.

Sometimes you just have to improvise.

First Time with Folding Hardware

This was my first time making a folding bracket system using hardware. The expandable wings needed to fold up and down smoothly, which meant everything had to be aligned perfectly.

Getting all the brackets aligned and screwed in at exactly the right spots was tedious work. One mistake and the wings wouldn't fold properly or would be uneven.

Making It Happen

No matter how many times I thought everything was going to fall apart, I made it happen in the end. That's kind of the theme of my woodworking journey so far – things look like they're going wrong, but you just keep pushing through.

The Result

Now I use it all the time. The expandable wings give me extra support for long boards, the storage underneath keeps things organized, and the wheels let me roll it around as needed.

It's become an essential part of my shop setup. Every time I use the table saw, I'm glad I pushed through all those frustrating moments to get this thing built.